Phosphorus Evaluation

The Harrisonburg-Rockingham Regional Sewer Authority North River Wastewater Treatment Facility (WWTF) is a 22 MGD ENR treatment facility that utilizes enhanced biological phosphorus removal (EBPR) as the primary means to meet stringent effluent total phosphorus concentration limits (0.28 mg/l).

The facility periodically feeds ferric chloride as required within the treatment process as a secondary mechanism for phosphorus removal. EBPR is enhanced at this facility by fermenting primary sludge and sending the generated VFAs to the anaerobic zone of the 5-stage activated sludge process.

The treatment facility experiences periodic slug loadings of phosphorus that exceed the facility’s EBPR capacity on occasion which requires the use of ferric chloride. Historical operations indicate that unusually high metal salt dosages resulting in increased treatment and labor costs.

Wiley|Wilson conducted a chemical phosphorus optimization study to investigate the details behind this phenomenon by more closely characterizing the influent phosphorous loading, evaluating the effectiveness of different metal salts, determining the optimum feed point locations within the treatment system when ferric addition is required and identification of significant users discharging refractory forms of phosphorus.

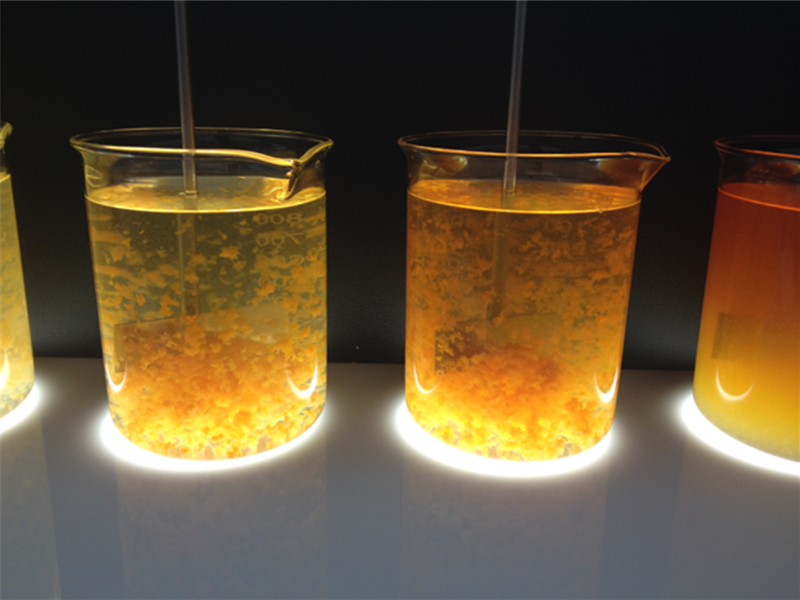

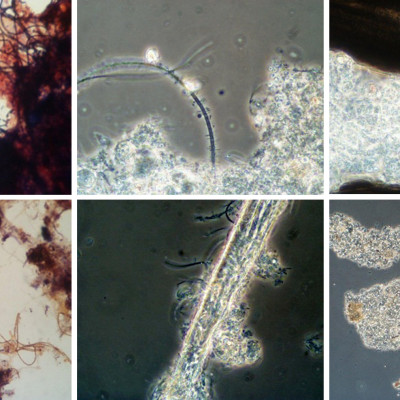

Bench scale testing was conducted to evaluate both chemical addition points and molar ratios to achieve different levels of phosphorus removal. The testing incorporated several metal salts including ferric chloride, aluminum sulfate, aluminum chloride, poly-aluminum chloride and SORB-X. The bench scale test results were validated comparing tests conducted during slug loading events to contemporaneous full scale plant performance.